Big Turbo: Best bang for buck

#21

How is the Comp Turbo Entry level turbo using "replacement parts"? It isn't like Comp Turbo takes a BW or Garrett turbo and replaces some of the parts and calls it their own. lol

The CT Entry level series is just some of their standard Journal bearing turbos with either their cast wheel or their billet wheel but at a fraction of the cost by cutting most of the profit out and that includes the dealer profit. So their Entry Level CT3-5556 is no different then their CT3-5556-2X, well other then the difference in price of $650 vs $999.

The CT Entry level series is just some of their standard Journal bearing turbos with either their cast wheel or their billet wheel but at a fraction of the cost by cutting most of the profit out and that includes the dealer profit. So their Entry Level CT3-5556 is no different then their CT3-5556-2X, well other then the difference in price of $650 vs $999.

As I stated I am curious as to where to Franken sources their parts. With larger T3T4 style turbos you can get by with a bit more since the balance does not have to spot on. Smaller K03 and K04 turbos spin at such a high RPM range that they must be properly VSR balanced or they simply do not last. I am sure Franken does this though since I have yet to see any durability issues.

If I were in the market for a turbo I would not pay the extra $300-$400 for a Garrett equivalent. I would buy either a Comp or Precision. Actually what I would do is sort the parts myself and manufacure my OWN turbo since this can be done for around 70% of the cost af an entry line turbo and use the same parts. That price would include a 3 stage balance with the final stage being VSR.

Meloman- 240awhp equates to more then 288chp. The drivetrain loss is well over 20% and I have seen numbers around 22%-23%. That is closer to 305-310 crank hp.

Last edited by zandrew; 02-14-2013 at 01:37 AM.

#23

Replacement parts was a kind way of saying that Comp's entry line uses knock off Garrett designed parts that are manufactured in..... CHINA. Since the design on the Garrett turbos such as the T3T4 and several others are well past the copywright boundary anyone can copy they products and relabel them for resale. Just because the parts are manufactured in China does not make them **** like eGay turbos. It only means that Comp, Precision, and even turbonetics are focused on increasing profits more then a small label stating its place of origin. There are a lot of companies that do this an produce a perfectly durable and capable product.

As I stated I am curious as to where to Franken sources their parts. With larger T3T4 style turbos you can get by with a bit more since the balance does not have to spot on. Smaller K03 and K04 turbos spin at such a high RPM range that they must be properly VSR balanced or they simply do not last. I am sure Franken does this though since I have yet to see any durability issues.

If I were in the market for a turbo I would not pay the extra $300-$400 for a Garrett equivalent. I would buy either a Comp or Precision. Actually what I would do is sort the parts myself and manufacure my OWN turbo since this can be done for around 70% of the cost af an entry line turbo and use the same parts. That price would include a 3 stage balance with the final stage being VSR.

Meloman- 240awhp equates to more then 288chp. The drivetrain loss is well over 20% and I have seen numbers around 22%-23%. That is closer to 305-310 crank hp.

As I stated I am curious as to where to Franken sources their parts. With larger T3T4 style turbos you can get by with a bit more since the balance does not have to spot on. Smaller K03 and K04 turbos spin at such a high RPM range that they must be properly VSR balanced or they simply do not last. I am sure Franken does this though since I have yet to see any durability issues.

If I were in the market for a turbo I would not pay the extra $300-$400 for a Garrett equivalent. I would buy either a Comp or Precision. Actually what I would do is sort the parts myself and manufacure my OWN turbo since this can be done for around 70% of the cost af an entry line turbo and use the same parts. That price would include a 3 stage balance with the final stage being VSR.

Meloman- 240awhp equates to more then 288chp. The drivetrain loss is well over 20% and I have seen numbers around 22%-23%. That is closer to 305-310 crank hp.

Tel me this does Garrett have a Triple Ball Bearing CHRA, or a Billet water cooled CHRA housing or offer a Oil-less CHRA? No so how in the world can Comp Turbo be offering copied parts if they are making something that Garrett doesn't offer? Comp actually uses really high quality bearings for their turbos that are made by a very high end bearing company.

Does it matter where Doug sources his parts from? Pretty sure that is his business and as long as the parts are not failing then it shouldn't really matter. It seems the only time people start wanting to know that info is because they want to get the same parts from that same source. Doug has his turbos put together by a turbo shop and they are balanced like any other turbo would be.

Last edited by Mike-2ptzero; 02-14-2013 at 06:54 PM.

#24

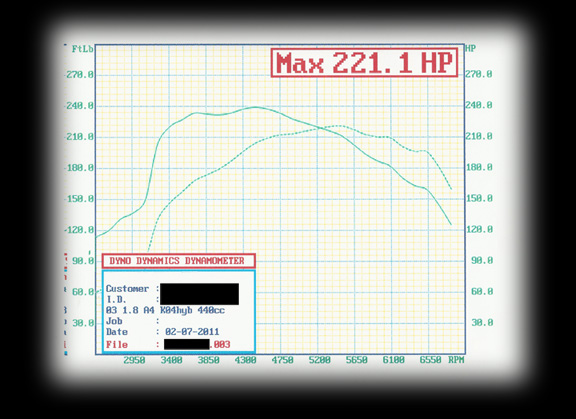

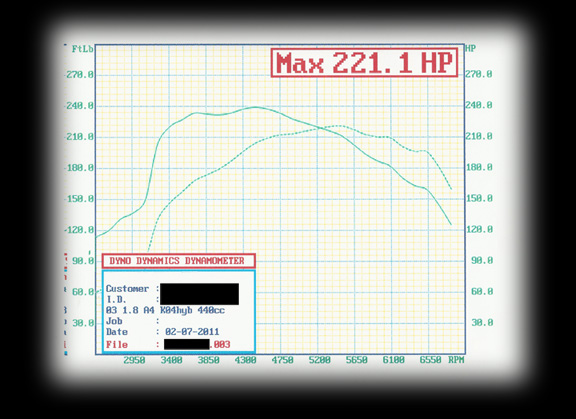

This is what I am referring to for my information about that 221hp, that is very far far away from (People have put down 240awhp and 265awtq with a franken turbo. Thats about 288chp). Picture was pulled directly from their website. Truth is in the picture. Yet this is what confuses me, their transverse 1.8t kit has a picture which states 261.7hp?? So if they are truly capable of more then why do they not simply write max power output to date with our longitudial kit 29732hp!!! You get the idea. I just don't get why you guys say they can do more yet their site specifically has 221hp. With this kit from fraken turbo unaltered, it will only provide a max output of 221hp. Unless altered by an tuning shop who would write you another tune. Correct? And I don't think anyone is trying to harp on anyone for their parts quality, just simply how can he source such a good turbo for cheap. And you explained it very well, he simply cuts his profits and probably has a really good supplier for parts and etc. Even I wish I knew where he got his stuff but that is just a normal curiosity. If it works, don't f*** with it.

#25

For starters, that dyno graph is from the Frankenturbo F4L, not the F21 which has a larger compressor wheel (and was just reduced to $999 and received a 2 year warranty) and Motoza's old 440cc tune. Their new K04 Hybrid tune is rated at 290hp/300tq.

If you don't want our advice, don't take it.

If you don't want our advice, don't take it.

#26

Well that was kind of the most solid answer I have gotten, so thank you sir. I am merely just trying to get answers to questions I don't fully understand. I honestly have appreciated all the input on this site and will hopefully continue to help in any odd way that I can. It's a good community here. Thank you again for your answers.

#27

This is what I am referring to for my information about that 221hp, that is very far far away from (People have put down 240awhp and 265awtq with a franken turbo. Thats about 288chp). Picture was pulled directly from their website. Truth is in the picture. Yet this is what confuses me, their transverse 1.8t kit has a picture which states 261.7hp?? So if they are truly capable of more then why do they not simply write max power output to date with our longitudial kit 29732hp!!! You get the idea. I just don't get why you guys say they can do more yet their site specifically has 221hp. With this kit from fraken turbo unaltered, it will only provide a max output of 221hp. Unless altered by an tuning shop who would write you another tune. Correct? And I don't think anyone is trying to harp on anyone for their parts quality, just simply how can he source such a good turbo for cheap. And you explained it very well, he simply cuts his profits and probably has a really good supplier for parts and etc. Even I wish I knew where he got his stuff but that is just a normal curiosity. If it works, don't f*** with it.

Plus you also have to in account that the dyno sheet posted on the longitude kit is for a AWD car (which is clearly stated under the picture when you click on it) while the dyno sheet for the transverse car is for a FWD car. This is one of the reasons you see FWD cars showing higher dyno readings then a AWD car. This is pretty much common knowledge unless you are new to Audi/VW cars.

Here is the caption that is under that dyno sheet when you click on it on FT web site.

B-6 series A4 with Motoza Performance 440cc 91 Octane file 221 all wheel HP

Last edited by Mike-2ptzero; 02-14-2013 at 11:37 PM.

#28

Sorry to break it to you but Comp Turbo stuff isn't made in China so I am not sure where your getting your info from. I have actually been to their shop many times. Let me guess you get your info from the Internet and what is on the internet must be 100% true. LOL

Tel me this does Garrett have a Triple Ball Bearing CHRA, or a Billet water cooled CHRA housing or offer a Oil-less CHRA? No so how in the world can Comp Turbo be offering copied parts if they are making something that Garrett doesn't offer? Comp actually uses really high quality bearings for their turbos that are made by a very high end bearing company.

Does it matter where Doug sources his parts from? Pretty sure that is his business and as long as the parts are not failing then it shouldn't really matter. It seems the only time people start wanting to know that info is because they want to get the same parts from that same source. Doug has his turbos put together by a turbo shop and they are balanced like any other turbo would be.

Tel me this does Garrett have a Triple Ball Bearing CHRA, or a Billet water cooled CHRA housing or offer a Oil-less CHRA? No so how in the world can Comp Turbo be offering copied parts if they are making something that Garrett doesn't offer? Comp actually uses really high quality bearings for their turbos that are made by a very high end bearing company.

Does it matter where Doug sources his parts from? Pretty sure that is his business and as long as the parts are not failing then it shouldn't really matter. It seems the only time people start wanting to know that info is because they want to get the same parts from that same source. Doug has his turbos put together by a turbo shop and they are balanced like any other turbo would be.

I specifically stated the entry line of Comp turbos which is within the scope of this thread and NO I did not get the info from the internet. I actually got the info from working 3 years at a machine shop that remanufactured turbos. The same place we bought replacement parts is the exact same place the parts on BOTH Precision and Comp entry line turbos as well as about all Turbonetics. The parts are sourced from CHINA and put together here. As I stated there is nothing wrong with it. The only real difference is a small label as to where the parts are manufactured. Last time I checked Inconel is the same here as it is in China.

Every manufacture of turbos have some sort of gimmick to try and compete with other manfuacturers. I am not up to speed on the oil less turbo cart but the triple bearing cart is no better then Garretts dual bearing cart. Three sets does not make it better then two. It actually takes away from the point of using ball bearings. The ball bearings are a far superior thrust supporter then the traditional thrust bearing setup and the ball bearings reduce drag thus increasing transient response. Adding a third set decreases transient response by 50%. It also considerably harder to get 3 bearings properly aligned and to keep them properly aligned.

I actually had a guy drop a Garrett T3T4 57 trim with a stage 2 turbine for a Comp CT2 5558 triplex and sold the Comp and went back to the Garrett T3T4 57 trim remarking that it did not spool that much different which I told him it would not. The reason was due to the difference in turbine size and he was running his setup at 18psi. He would have seen a considerable difference had he run the Comp at psi levels it was designed to thrive at which is the point of ball bearing units; being able to run them at extreme psi levels with smaller turbines for longer periods of time where a standard journal bearing turbo would not handle the abuse. However the majority of street driven machines will NEVER have the necessity of ball bearing unit especially when considering cost.

Meloman- Not being a douche but your math is wrong. 123% of 240 does not equal the same 23% of 294. The math is a lil different. It is 240 whp/(100%-23%) or 77% = x/100% where x equals crank hp Or simply 24000/77 = 311.7 and for 22% it is 24000/78 - 307.7.

Last edited by zandrew; 02-15-2013 at 12:52 AM.

#29

I specifically stated the entry line of Comp turbos which is within the scope of this thread and NO I did not get the info from the internet. I actually got the info from working 3 years at a machine shop that remanufactured turbos. The same place we bought replacement parts is the exact same place the parts on BOTH Precision and Comp entry line turbos as well as about all Turbonetics. The parts are sourced from CHINA and put together here. As I stated there is nothing wrong with it. The only real difference is a small label as to where the parts are manufactured. Last time I checked Inconel is the same here as it is in China.

Every manufacture of turbos have some sort of gimmick to try and compete with other manfuacturers. I am not up to speed on the oil less turbo cart but the triple bearing cart is no better then Garretts dual bearing cart. Three sets does not make it better then two. It actually takes away from the point of using ball bearings. The ball bearings are a far superior thrust supporter then the traditional thrust bearing setup and the ball bearings reduce drag thus increasing transient response. Adding a third set decreases transient response by 50%. It also considerably harder to get 3 bearings properly aligned and to keep them properly aligned.

I actually had a guy drop a Garrett T3T4 57 trim with a stage 2 turbine for a Comp CT2 5558 triplex and sold the Comp and went back to the Garrett T3T4 57 trim remarking that it did not spool that much different which I told him it would not. The reason was due to the difference in turbine size and he was running his setup at 18psi. He would have seen a considerable difference had he run the Comp at psi levels it was designed to thrive at which is the point of ball bearing units; being able to run them at extreme psi levels with smaller turbines for longer periods of time where a standard journal bearing turbo would not handle the abuse. However the majority of street driven machines will NEVER have the necessity of ball bearing unit especially when considering cost.

.

Every manufacture of turbos have some sort of gimmick to try and compete with other manfuacturers. I am not up to speed on the oil less turbo cart but the triple bearing cart is no better then Garretts dual bearing cart. Three sets does not make it better then two. It actually takes away from the point of using ball bearings. The ball bearings are a far superior thrust supporter then the traditional thrust bearing setup and the ball bearings reduce drag thus increasing transient response. Adding a third set decreases transient response by 50%. It also considerably harder to get 3 bearings properly aligned and to keep them properly aligned.

I actually had a guy drop a Garrett T3T4 57 trim with a stage 2 turbine for a Comp CT2 5558 triplex and sold the Comp and went back to the Garrett T3T4 57 trim remarking that it did not spool that much different which I told him it would not. The reason was due to the difference in turbine size and he was running his setup at 18psi. He would have seen a considerable difference had he run the Comp at psi levels it was designed to thrive at which is the point of ball bearing units; being able to run them at extreme psi levels with smaller turbines for longer periods of time where a standard journal bearing turbo would not handle the abuse. However the majority of street driven machines will NEVER have the necessity of ball bearing unit especially when considering cost.

.

To me that sure sounds like your guessing or just assuming seeing that you did not work for the company that supplies parts to either company. Most people already know PTE at one point used the same parts Turbonetics used because it had been proven many times including some A4 owners that took their PTE turbo apart to find parts with the Turbonetics name on it. That was some time ago during the early years of PTE.

Now if you would like I would be more then willing to call up Joe the owner of Comp and have them post on this thread or get a statement from them. See I don't actually guess, I actually ask the company directly and asked them if their parts are sourced here or over seas and got a straight answer as one of their dealers. I deal with them pretty much every week and sell a good amount of their turbos without any customer complaints.

Not sure why in the world that guy would think a 5558 was going to spool up faster seeing that the 58mm exhaust wheel is pretty big. That is a huge jump up from a 50 trim seeing one is rated at 46 lb/min and the other is rated at 54 lb/min. He should have just sent in his 50 trim to Comp and had them do a Billet wheel compressor wheel upgrade if he wanted to increase the spool and gain a bit more power or went with smaller CT like the 5556 or slightly smaller then that. Sounds like he didn't know how to choose a turbo or was listening to the wrong people that also had no clue.

I have had that CT upgrade done for other 50 trim customers and they were more then happy with the results.

I have a customer that went from a 60-1 (way larger then the 50trim) to a CT 5556 entry level turbo and he is pretty happy with the results. Actually have a few people running that turbo and all of them are really happy with it. Even have a customer running a 5562 on his 1.8t and that thing seems to spool up pretty quick hitting 26-28psi around 4600 rpm, that is with a huge 62 exhaust wheel and now just think how much quicker it would spool with a smaller exhaust wheel.

CT 56mm exhaust wheel vs CT 58mm exhaust wheel. As you can see there is a huge diffence in the actual size of the wheel and the amount of blades, the 56mm is their largest T3 wheel and the 58mm is their smallest T4 wheel.

56mm on the left and 58mm on the right

BTW here is a post by another A4 1.8t owner that went with the CT3-5556 entry level turbo and was running a T3/T4 50 trim before that. This was posted on another A4 forum.

I am loving my ct3-5556 JB.

It really pulls earlier and harder than my t3t4 50 trim.

I'm doing 30psi now with meth injection.

I am using pure methanol.

It really pulls earlier and harder than my t3t4 50 trim.

I'm doing 30psi now with meth injection.

I am using pure methanol.

Last edited by Mike-2ptzero; 02-15-2013 at 11:49 AM.

#30

I respect the fact that you have been there with your A4 but you are sir an *** hole and I am sorry to state this but you are not the end all for information especially regarding turbos. First off the reason the customer went to the CT5558 was because a person using their car for the track was. It was on a B16 and I highly suggested not too since as I clearly stated (maybe your reading comprehension is rusty) he was not going to use it in its designed application. He only went back to the 57 trim since he already had it. I actually suggested T3T4 50 trim with a billet compressor and stage 2 turbine. There is nothing wrong with the stated turbo. My point of emphasis which I guess flew over your head was that you need to buy a turbo to match your design intention. Not buy something half witted.

Now second, the machine shop I worked for sourced their parts from a supplier in the US. That supplier ALSO supplies parts for Turbonetics, Precison, and COMP. These are direct replacement parts made to the same specification as Garrett parts. You can literally take Comp 57 trim compressor and swap it in a Garrett, Turbonetics, or Precision and even a Master power which is madein Brazil.

Go ahead and call whomever. Once you do you will realize it is not a GUESS, it is FACT.

In all honesty I have no clue as to why you are so hurt by it. There are several companies that do this. Some that do it simply for profit, and some that do it since their products qality does not suffer and it allows them to market a more cost conscience product that anyone can afford. Eagle does it with their. Even companies like Starrett does it. Blox has done it from the start.

This is not misinformation. It is fact.

Also the 60-1, or what precision calls their 6031e is a turd of turbo. Its compressor design was never intended for a performance application. Look at its fin angle and you will realize (if you know anything at all about turbos) that it was designed for low boost applications. It is one of the worst turbos for performance oriented specification. Also I clearly stated 57 trim, not 50 trim. Of the T04E compressors the 50 trim is my favorite as the exducer is slightly bigger then the others which widens the compressor range. There is also a Super 50 trim but it uses a much larger exducer and is bit difficult to spool. The 50 trim has excellent flow capabilites and spools excellent in comparison to its potential.

Now to make this abundantly clear, I have nothing against Comp turbos. They make a fine product and some of their proprietary items are outstanding units. However they, just like precison and turbonetics started by selling Garrett knock offs.

Now second, the machine shop I worked for sourced their parts from a supplier in the US. That supplier ALSO supplies parts for Turbonetics, Precison, and COMP. These are direct replacement parts made to the same specification as Garrett parts. You can literally take Comp 57 trim compressor and swap it in a Garrett, Turbonetics, or Precision and even a Master power which is madein Brazil.

Go ahead and call whomever. Once you do you will realize it is not a GUESS, it is FACT.

In all honesty I have no clue as to why you are so hurt by it. There are several companies that do this. Some that do it simply for profit, and some that do it since their products qality does not suffer and it allows them to market a more cost conscience product that anyone can afford. Eagle does it with their. Even companies like Starrett does it. Blox has done it from the start.

This is not misinformation. It is fact.

Also the 60-1, or what precision calls their 6031e is a turd of turbo. Its compressor design was never intended for a performance application. Look at its fin angle and you will realize (if you know anything at all about turbos) that it was designed for low boost applications. It is one of the worst turbos for performance oriented specification. Also I clearly stated 57 trim, not 50 trim. Of the T04E compressors the 50 trim is my favorite as the exducer is slightly bigger then the others which widens the compressor range. There is also a Super 50 trim but it uses a much larger exducer and is bit difficult to spool. The 50 trim has excellent flow capabilites and spools excellent in comparison to its potential.

Now to make this abundantly clear, I have nothing against Comp turbos. They make a fine product and some of their proprietary items are outstanding units. However they, just like precison and turbonetics started by selling Garrett knock offs.

Last edited by zandrew; 02-15-2013 at 05:25 PM.