CV Axles - For C4 12v fellow owners

#1

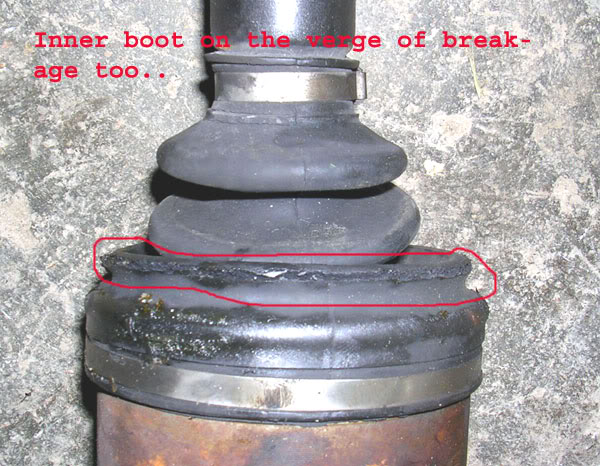

I finally came around to tackle the cv axles. Got them both for about $ 170 shipped, some months back. The brand is EMPI, they are brand new (all the components are brand new, no remanufactured stuff), and they ARE DIRECT FIT. The same brand axle, which comes as a primary replacement part on searches, sells for 2/3 more on the "consecrated" auto parts sites.

Enough said about that.

The 1995 C4 turns out to be extremely easy to work on in this case; well, up to a point at least.

As far as the cv axles, the job is fairly straight forward and it takes about 1 hr per axle. There are no 4 control arms and "infamous" pinch bolt to wrestle with, and the shield by the tranny side doesn't need to be removed.

I ended up replacing only one side, because I also changed the wheel hub + bearing, so that's where I ran into trouble. Got the hub and part of the bearing out ok after mustering a crowbar, but the bearing outer race remained "glued" to the spindle walls.

A press didn't even come close to move it one micron of an inch, so heat was the second option. Well, the propane torch + press wasn't much of a luck either. The last resort was an oxy-acetylene cutting torch...thank god for being available on a Sunday. I had to take the whole suspension shebang out (spindle + strut + coil) to set it in a vise somewhere outdoors to be able to cut it.

The old bearing was a double ball-ring type.

No pics taken this time; maybe when I do the passenger side.

Back to the cv axle.

- Broke the axle bolt - 24 metric head (old style bolt)

- Loosened the wheel bolts

- Jacked up the car on that side

- removed the wheel

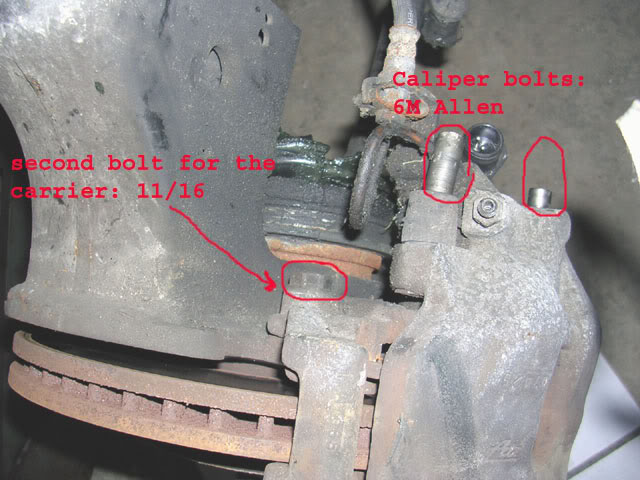

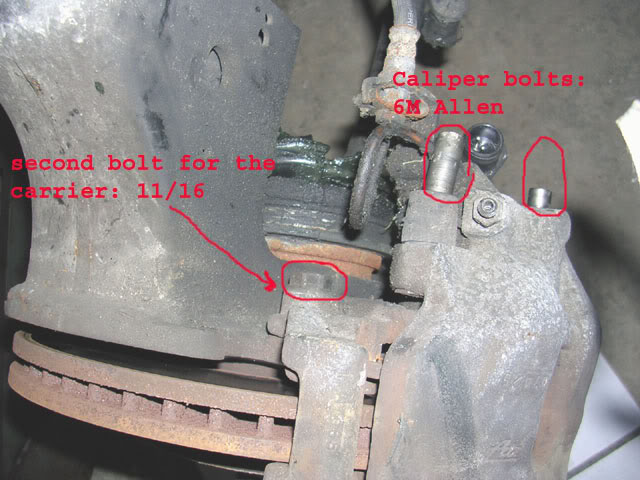

- removed the caliper + the ABS sensor (it just pulls out); removed the rotor

- removed the axle bolt

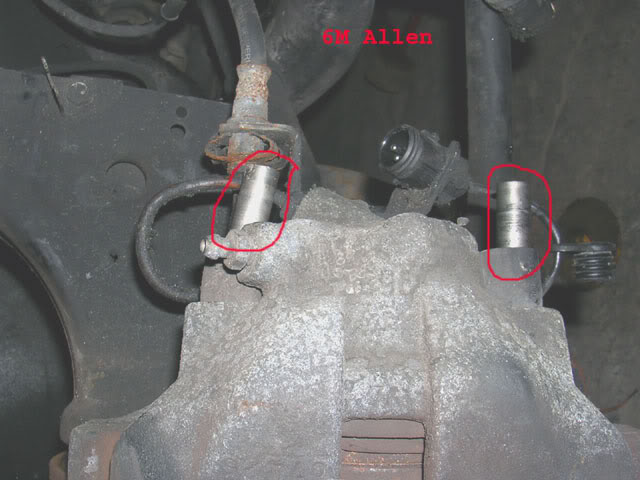

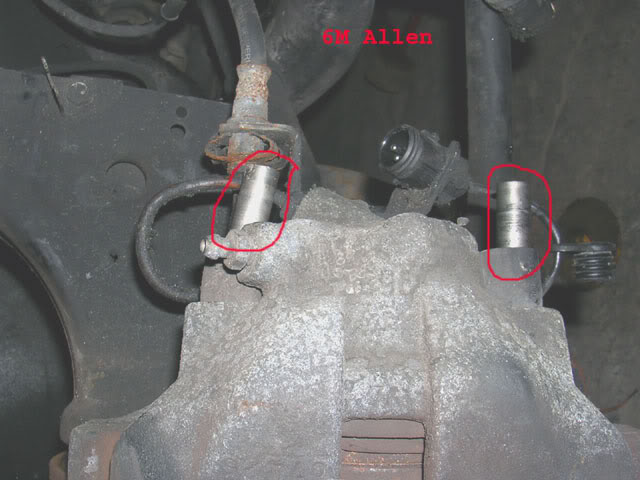

-loosened up and removed the tranny side bolts (the 10 metric XZN ones)

- pulled slightly away from and pushed up against the tranny the axle's inner side, turned the wheel left as far as it goes and slid out the outer end from the wheel hub.

- wheel hub + bearing trouble------fixed

- installed the new axle in reverse order.

Notes:

- My 6 xzn bolts came out easily so it was no need for new ones.

- The torques are:

XZN bolts - 59 ft lb

axle bolt - 148 ft lb + 1/4 turn (pretty much the same like the crankshaft bolt) ; the extra 90° turn is a bitch....

Enough said about that.

The 1995 C4 turns out to be extremely easy to work on in this case; well, up to a point at least.

As far as the cv axles, the job is fairly straight forward and it takes about 1 hr per axle. There are no 4 control arms and "infamous" pinch bolt to wrestle with, and the shield by the tranny side doesn't need to be removed.

I ended up replacing only one side, because I also changed the wheel hub + bearing, so that's where I ran into trouble. Got the hub and part of the bearing out ok after mustering a crowbar, but the bearing outer race remained "glued" to the spindle walls.

A press didn't even come close to move it one micron of an inch, so heat was the second option. Well, the propane torch + press wasn't much of a luck either. The last resort was an oxy-acetylene cutting torch...thank god for being available on a Sunday. I had to take the whole suspension shebang out (spindle + strut + coil) to set it in a vise somewhere outdoors to be able to cut it.

The old bearing was a double ball-ring type.

No pics taken this time; maybe when I do the passenger side.

Back to the cv axle.

- Broke the axle bolt - 24 metric head (old style bolt)

- Loosened the wheel bolts

- Jacked up the car on that side

- removed the wheel

- removed the caliper + the ABS sensor (it just pulls out); removed the rotor

- removed the axle bolt

-loosened up and removed the tranny side bolts (the 10 metric XZN ones)

- pulled slightly away from and pushed up against the tranny the axle's inner side, turned the wheel left as far as it goes and slid out the outer end from the wheel hub.

- wheel hub + bearing trouble------fixed

- installed the new axle in reverse order.

Notes:

- My 6 xzn bolts came out easily so it was no need for new ones.

- The torques are:

XZN bolts - 59 ft lb

axle bolt - 148 ft lb + 1/4 turn (pretty much the same like the crankshaft bolt) ; the extra 90° turn is a bitch....

Last edited by chefro; 07-05-2009 at 10:13 PM.

#2

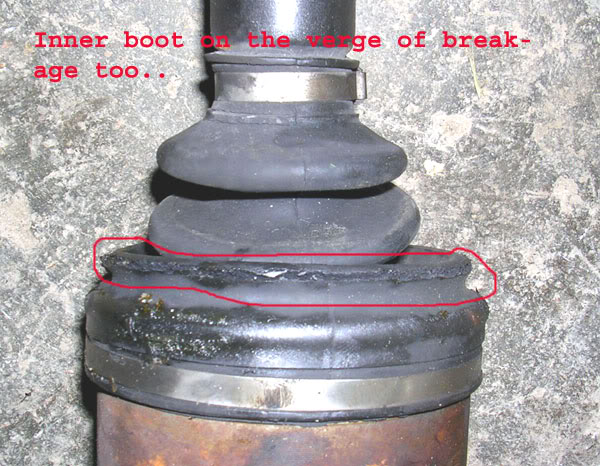

This time around I took some photos, up until I got really messy (grease from the axle).

Although I would have wanted to rather highlight the wheel hub and bearing replacement, I was too greasy to use the cam (sorry).

There are quite a few CV Axle replacement write-ups on AudiWorld, so there's no need to make another one. As I mentioned previously, the suspension system on the C4 is much simpler than C5s and C6s, with their 4 control arms.

Although probably the wheel hub can be popped out with a heavy duty puller, I had to take out the whole strut-knuckle assembly. Just like last time on the driver's side, I had to cut the bearign's outer race that (just like last time) remained lodged inside the knuckle race. The oxy-acetylene torch did the job again. Anyway, in this case the wheel hub comes out via hammer by tapping the sides.

As far as the assembly, I lubed well the new bearing and hub and joined them by progressively tapping the bearing with a hammer. The oil spread on both of them helps to start the bearing slipping on straight. Got the new hub-bearing assembly inside the knuckle under a hydraulic press. Don't get me wrong, but I think on old cars like mine there's no way to get that stuck outer race loose without cutting it. If you don't have problems with your bearings (noises, etc), don't even mess up with them. They were built to last and bearing's race physically "fuses" to the knuckle...

The strut+knuckle assembly is easy (if no problems) to remove:

*** remove the tie rod end' s fastening nut and pop it out

(I had problems: I left the nut screwed on after loosening it to tap it with a hammer. After I tapped it just once, the tie rod end popped out, but then the nut would spin together with the threaded shaft. I had to heat it up to melt the plastic insert, and then used some needle nose locking pliers as a counter -not to damage the TRE's dust boot)

*** popping out the knuckle from the sway bar-control arm assembly's "pinch bolt" by applying downward pressure with a big bar

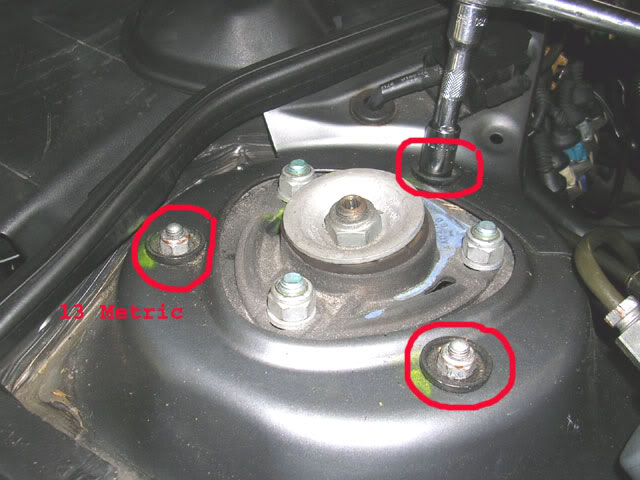

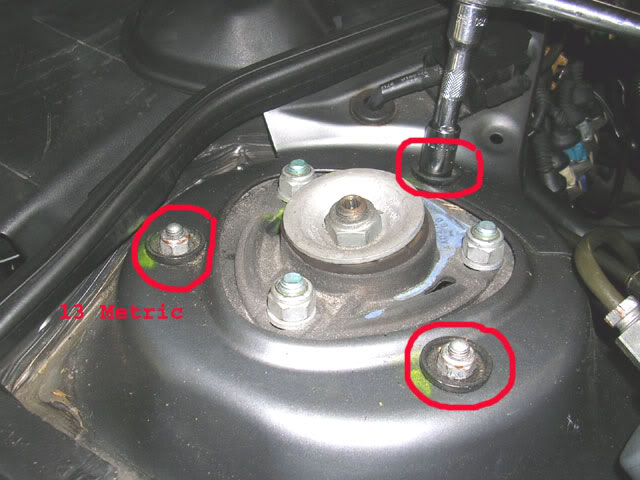

*** removing the three top nuts securing the strut + coilspring to the chassy.

At this point the assembly just drops. It is pretty heavy so is good to have something under it before removing those three nuts; something like a jackstand or a box.

That's the story.

--

--

--

--

--

--

--

--

--

--

--

--

--

Although I would have wanted to rather highlight the wheel hub and bearing replacement, I was too greasy to use the cam (sorry).

There are quite a few CV Axle replacement write-ups on AudiWorld, so there's no need to make another one. As I mentioned previously, the suspension system on the C4 is much simpler than C5s and C6s, with their 4 control arms.

Although probably the wheel hub can be popped out with a heavy duty puller, I had to take out the whole strut-knuckle assembly. Just like last time on the driver's side, I had to cut the bearign's outer race that (just like last time) remained lodged inside the knuckle race. The oxy-acetylene torch did the job again. Anyway, in this case the wheel hub comes out via hammer by tapping the sides.

As far as the assembly, I lubed well the new bearing and hub and joined them by progressively tapping the bearing with a hammer. The oil spread on both of them helps to start the bearing slipping on straight. Got the new hub-bearing assembly inside the knuckle under a hydraulic press. Don't get me wrong, but I think on old cars like mine there's no way to get that stuck outer race loose without cutting it. If you don't have problems with your bearings (noises, etc), don't even mess up with them. They were built to last and bearing's race physically "fuses" to the knuckle...

The strut+knuckle assembly is easy (if no problems) to remove:

*** remove the tie rod end' s fastening nut and pop it out

(I had problems: I left the nut screwed on after loosening it to tap it with a hammer. After I tapped it just once, the tie rod end popped out, but then the nut would spin together with the threaded shaft. I had to heat it up to melt the plastic insert, and then used some needle nose locking pliers as a counter -not to damage the TRE's dust boot)

*** popping out the knuckle from the sway bar-control arm assembly's "pinch bolt" by applying downward pressure with a big bar

*** removing the three top nuts securing the strut + coilspring to the chassy.

At this point the assembly just drops. It is pretty heavy so is good to have something under it before removing those three nuts; something like a jackstand or a box.

That's the story.

--

--

--

--

--

--

--

--

--

--

--

--

--

Last edited by chefro; 08-16-2009 at 01:35 PM.

Thread

Thread Starter

Forum

Replies

Last Post

AteUrV8

Audi A4

14

02-07-2007 06:29 AM